The following topics are discussed in this blog: coaxial cable connectors, how it work, types of coaxial cable connectors, advantages, features, how to choose a connector, setup, and standards.

Coaxial cable connectors

Electrical fittings called coaxial cable connectors are made to terminate and join coaxial cables to other cables or devices. They can be used to “top and tail” cables, link cables together, or connect equipment to external power sources while maintaining the exterior interference shielding. They are also referred to as barrel or tip connectors. In order to minimize signal loss and preserve signal integrity, this shielding is essential.

How Coaxial Connectors Work

The inner conductor of a coaxial connector is protected by a concentric conducting sleeve, and the conductor and the shield are separated by an insulating substance. In their most basic configuration, they are made up of a signal pin, a dielectric insulator, and a metal shield typically the connector’s outer shell.

A female contact of comparable substance and plating mates with the centre signal pin, which is usually beryllium copper that has been gold-plated. Typically, these connections are crimped or soldered to the centre conductor of the coaxial cable. Teflon is frequently used as the surrounding dielectric material in order to provide the required performance. As a defence against outside interference, the connector’s shield or housing terminates to the cable’s shield.

Key Features

Coaxial connections work together to ensure data transmission and come in various sizes to fit cable sizes. They also withstand pressure, vibration, impact, and heat. Although they can be fragile, special connections are necessary for radio frequency (RF) transmission in order to maintain constant electrical resistance at the connection site.

Key characteristics include:

- Impedance Matching: Signal loss is reduced by impedance matching 50 or 75 Ohm coaxial cables and connectors. Video and home cable TV use 75 Ohm, whereas data, Wi-Fi, and two-way radio use 50. 50 Ohm was originally chosen to balance attenuation (minimum 77 ohms) with power-handling (optimal 30).

- Shielding: They shield the cable from interference and contain the signal for signal quality.

- Durability: Many types are waterproof and durable for outdoor use. Materials like gold-plated metals resist corrosion, extending service life.

- Usability: Quick-connect and screw-on connectors are available.

- Mating Mechanism: Threaded, bayonet (twist-on), snap-on, blind mate, bracing, and latching are some of the coupling techniques that connectors can have.

Gender Types Types by Gender Coaxial connections are often classified as either male or female.

Male connectors Typically, male connections feature a projecting pin or protrusion that slides into slots or indentations on female connectors. They frequently have an electrical contact point on the side that is spring-loaded.

Female connectors usually have an exterior cylinder (the barrel or sleeve) that serves as an electrical contact point and a metallic tube that houses the male pin (the tip), which is encased in an insulating layer.

Genderless coaxial connectors, sometimes referred to as combination connectors, can be connected to either male or female connectors of the same size and type since they combine female slots and male protrusion points at the same connecting point. They make it possible to quickly repurpose cabling in intricate systems, but they are not appropriate for situations where a precisely regulated, one-way current flow is necessary for functioning or safety. The electrical polarity of genderless connectors is reversed, and the male plug has a slot and the female socket has a pin that protrudes.

Also Read About What is RJ 11 Connectors, Key Features, and Advantages

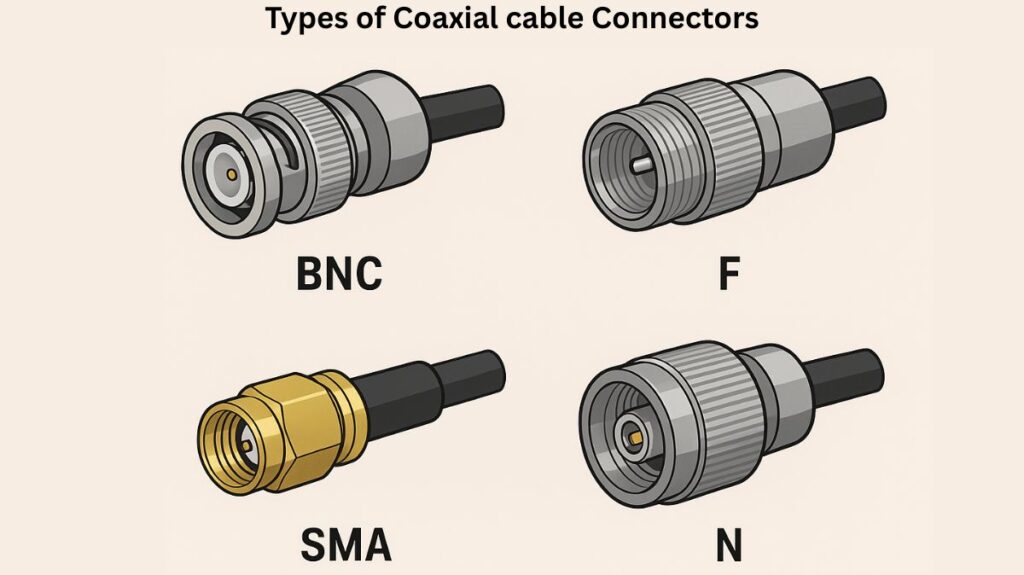

Types of Coaxial cable Connectors

Because of their many applications and the harsh environments in which they frequently function, coaxial connectors come in a wide variety. Among the main kinds are:

7/16 DIN Connectors

These durable, threaded connectors are mostly used to join coaxial cable lengths in damp settings, like broadcasting equipment and radio base stations. These connectors have minimal PIM (Passive Intermodulation) and high power.

BNC (Bayonet Neil-Concelman) Connectors

Test instruments, radios, televisions, professional video, AV equipment, and CCTV cameras are among the many devices that frequently use BNC (Bayonet Neil-Concelman) connectors, which are smaller connectors with a bayonet-lock mechanism for quick connection and separation. Their peak performance occurs below 4 GHz. Video is 75-ohm while radio is 50-ohm.

F Connectors (F-type)

Used in homes for cable, satellite, and broadband internet, these connectors transport electrical impulses to TVs, modems, and set-top boxes. Screw-on connectors and 75 ohm ratings make them ideal for video communications. RG6 and RG59 cables can be used with them.

FME Connectors

Small threaded connectors for mobile devices are known as FME connectors.

MBX Connectors

These strong connectors join radio frequency equipment and display exceptional electrical performance and power handling.

Micro Coaxial (MCX) Connectors

Compact, snap-on connectors for space-constrained applications such digital cellular, Wi-Fi, GPS, PC TV tuner cards, and routers. They function in the DC to 6 GHz range.

MMBX Connectors

Like MBX, these connectors allow multiple connections between adapters and offer dependable and adaptable connections in radio communications equipment, even if they are misaligned.

N Connectors (N-type)

Paul Neill-named medium-sized, waterproof adapters with threads. With a broad frequency range of 11–18 GHz, it is perfect for antennas, military equipment, wireless communication systems, radio transmission equipment, and commercial applications.

OSMT Connectors

Usually composed of polymer and plated in gold or nickel, these connectors are widely used in consumer electronics, telecommunications, and GPS equipment.

Also Read About Registered Jack 45: The Standard Ethernet Connector

OSP connectors

Used in radio equipment, these connectors have a snap-on or slide mechanism for joining.

QLI Connectors

DIN 7/16 connection variants with a bayonet locking mechanism that work similarly and are renowned for their resilience in challenging conditions.

QMA Connectors

fast-lock and fast-disconnect connectors (QMAs) are SMA variations that allow for speedy, tool-free attachment and removal. They are strong and vibration-resistant, making them perfect for transmission equipment, radio base stations, air traffic control systems, and outdoor environments.

QN Connectors

Quick-lock N-type connectors, or QN connectors, are appropriate for both indoor and outdoor use and work well with high voltage cables.

RCA connectors

Originally designed to transmit audio signals, these connectors are now commonly found in older TVs, DVD players, and sound systems for both audio and video transmissions. They frequently have colour-coded connectors (audio is red and white, while video is yellow).

SHV connections (Safe High Voltage)

Designed for safe usage with high voltage cables, these connections have a unique projecting insulator and a bayonet-locking mechanism akin to that of MHV and BNC connectors.

Also Read About

SMA Connectors (Subminiature Version A)

Wi-Fi antennas, cellular systems, GPS units, walkie-talkies, handheld radios, and radio telescopes all frequently use SMA connectors (Subminiature Version A), which are tiny, threaded connectors for microwave frequencies. At high frequencies, they work exceptionally well (up to 18 GHz for high-end variants). Although they differ by 2 mm, they can be mistaken for F coax connectors. This cable connector sells the most dollars after F-type and specials.

SMB Connectors (Subminiature Version B)

Similar to SMA, SMB connectors (Subminiature Version B) have an easy-to-use snap-on coupling design and are frequently seen in industrial electronics and communications equipment. From DC to 4 GHz, they offer exceptional electrical performance.

SMC Connectors (Subminiature Version C)

A second variant of SMA connections, SMC connections (Subminiature Version C) have a screw-type interface that ensures an airtight closure against damage and leaks. 50 Ohm and 75 Ohm variants are available.

SMP Connectors (Subminiature Push-on)

Suitable for demanding situations, these connectors include a snap-on interface, high electrical performance, and the ability to tolerate shock and vibration. GPO is another name for it.

Threaded Neil-Concelman (TNC) connectors

These are a weatherproof, threaded variant of BNC connectors that are intended for outdoor use and offer improved performance at higher microwave frequencies (up to 12 GHz). Cellular/RF antenna connections, mobile phone antennas, and radio antennas are among the common applications.

Triax Connectors

BNC connection variants used with triaxial (triax) cables that provide wider bandwidth because of an extra conducting sheath and insulating layer, but are usually more costly.

Twinax Connectors

Also referred to as Twin BNC, these doubled versions of the BNC connector are intended to stop signal mixing. They have both male and female contact points, a latching mechanism, and crimp connections for simple installation.

Ultra High Frequency (UHF) connectors

Despite their name, these are now mostly utilised with low-frequency equipment, such as CB radios and amateur radios, due to advancements in technology. Signal loss makes it unsuitable for high-frequency applications. frequently utilised as military equipment video connections. Also referred to by specific parts such as SO-239 and PL-259.

UMCC Connectors (Ultraminiature Coax Connector)

Ultraminiature Coax connectors, or UMCC connectors, are used for GPS and Wi-Fi antenna connections and for frequency transmissions up to 6 GHz in incredibly small spaces, such as laptop circuit boards and embedded circuitry.

K Connectors (Millimeter Wave Connectors)

K connections (2.92 mm) are compatible with SMAs and operate at frequencies up to 40 or 44 GHz. This precision connector uses air as a dielectric and requires tighter manufacturing tolerances. Smaller sizes include 2.4mm, 1.85mm, 0.8mm, 0.6mm, and 0.4mm.

Advantages of Coaxial Connectors

Coaxial connectors offer several advantages across various industries:

Reliable Signal Transmission: Their insulated design eliminates electromagnetic interference, allowing lengthy broadcasts.

Durability: They are built of corrosion-resistant gold-plated metals for harsh settings.

Durable and affordable: They cost less to maintain and replace than other connectors.

Simple Installation: Push-through, soldering, and crimping are easy to use. Installation tools are affordable and available.

Versatility: Used in networking, telecommunications, and security. Their multi-frequency architecture makes them common in RF and high-frequency systems.

Strong Performance: Offer a mechanically tight connection, lowering the possibility of loose connections or signal disruptions; locking devices are frequently used to stop unintentional disconnections.

Coaxial connector applications

For high-frequency, low-loss connections in a variety of industries, coaxial cable connectors are essential:

Broadcasting: In order to send high-quality audio and video signals across long distances with little interference, broadcasting is widely employed in satellite, cable TV (CATV), and telecommunications networks. Broadband internet networks and F-type connections are prevalent in this area.

Audio and visuals Equipment: Common options, such as BNC connections, are utilised in TV sets, concert venues, and production and broadcast equipment to handle high-frequency signals without deteriorating, guaranteeing steady and clear visuals. RCA connectors are also used.

Security Systems: CCTV systems employ BNC coaxial connectors to connect cameras and recording devices for sharp footage.

Networking: Essential for Ethernet and RF communication networks’ stable device connections and safe, low-loss data transfer over long distances.

Military and Aerospace: Their strength and resilience make them ideal for satellites, aeroplanes, and defence gear with high temperatures and vibrations.

Emerging Technologies: Even with new transmission methods, coaxial connectors are needed in the following areas:

- 5G networks:5G networks efficiently transmit high-frequency signals via base stations, antennas, and small cell systems, resulting in reduced latency and rapid data rates.

- Smart cities and broadband: For last-mile connections that offer fast internet and facilitate communication between sensors, gadgets, and urban management systems.

- Autonomous cars: Enabling real-time data processing through links for sensors, cameras, and radar systems.

Also Read About The Functionality Of RJ22 Connector, RJ48 And RJ50 Connector

How to Choose Your Connector

Understanding the essential characteristics of the cable is necessary to choose the appropriate coaxial connector:

- The voltage

- Environment: Consider temperature, vibration, humidity, and if hard or outdoor settings require weather-resistant connectors like N-type or TNC.

- Required bandwidth and frequency: Each connector has a frequency range.

- Match the connector’s 50- or 75-ohm impedance to the cable and application.

- Ascertain if mating with existing hardware requires a male or female connection.

- Based on security and usability, choose threaded, bayonet, snap-on, or blind mates.

- Size and Form Factor: Small devices use connections from larger (7/16 DIN) to smaller (SMA, MCX, MMCX).

- The size and type of cable.

- Adherence to industry and safety requirements.

- Price.

- The ability to handle power.

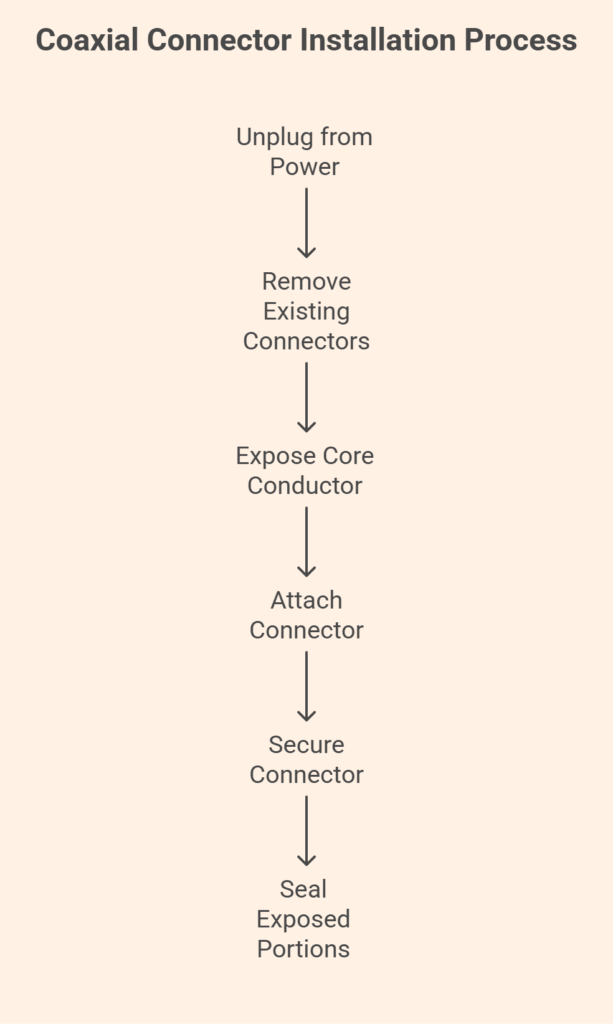

Coaxial Connector Installation Process

There are multiple processes involved in connecting or changing a coaxial connector:

- Safety: Unplug the cord from all power sources to avoid shock.

- Remove any existing connectors with wire strippers, a construction knife, or twisting.

- Cut tiny holes with a wire stripper to disclose the core copper conductor and wire braiding, being careful not to damage the layers underlying. To reach the connector’s length, peel aside the jacket and braiding.

- Attach Connector: Make sure the inner conductor is correctly seated within the connector’s pin before sliding the connector onto the exposed wire.

- Secure Connector: Use pliers, a specialised crimping tool, or a compression tool to apply pressure. Press firmly to insert the cable and connector into the tool.

- Seal (Optional): Cover any exposed portions with liquid electrical tape and let it dry.

Standards

RF coaxial connectors are defined by industry and military standards organizations. While MIL-DTL-17 regulates MIL-Spec coaxial cables, MIL-PRF-39012 and MIL-STD-348 are the main specifications for the majority of coaxial connectors. IEEE 287 standards are followed by precision coax connections used in crucial test and calibration applications.

Also Read About Advantages Of Network Address Translation NAT And Types